DETAILED

Steam Injection Sterilization Module (SIM)

Researchers using this device can accurately assess the impact of virtually any continuous heat treatment process (such as high-temperature short-time sterilization or ultra-high-temperature sterilization) on their products.

Category:

MicroThermics UHT/HTST

Keyword:

Foreign trade

DYNAMIC DAYLIGHT

Tel:

PRODUCT DETAILS

Direct/Indirect Modules

Researchers using this equipment can accurately assess the impact of virtually any continuous thermal processing (such as high-temperature short-time sterilization or ultra-high temperature sterilization) on their products. By reducing failed experiments and integrating the process into product development, R&D departments can lower costs and bring products to market faster.

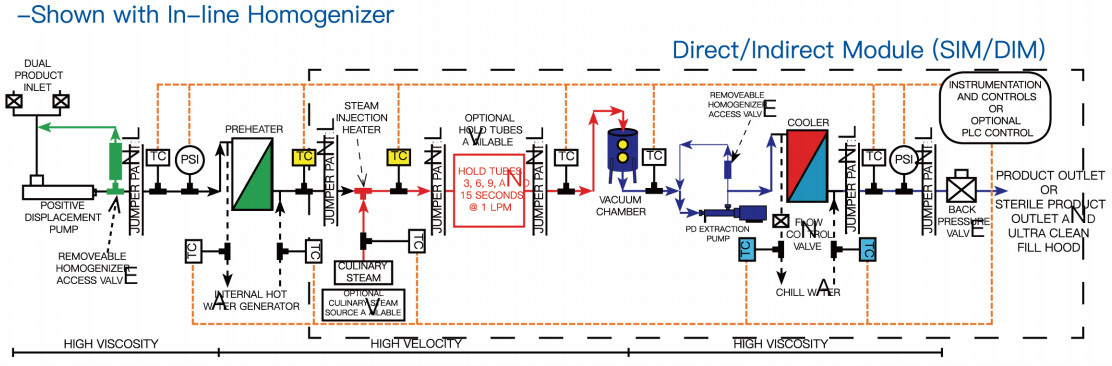

The MicroThermics Steam Injection Module (SIM) is a lab-scale processing module that extends the capabilities of other MicroThermics primary processing systems by adding steam injection and vacuum cooling. It's a functional upgrade to the existing tubular heating, providing flexibility to research the optimal balance between direct and indirect heating on product quality and fouling.

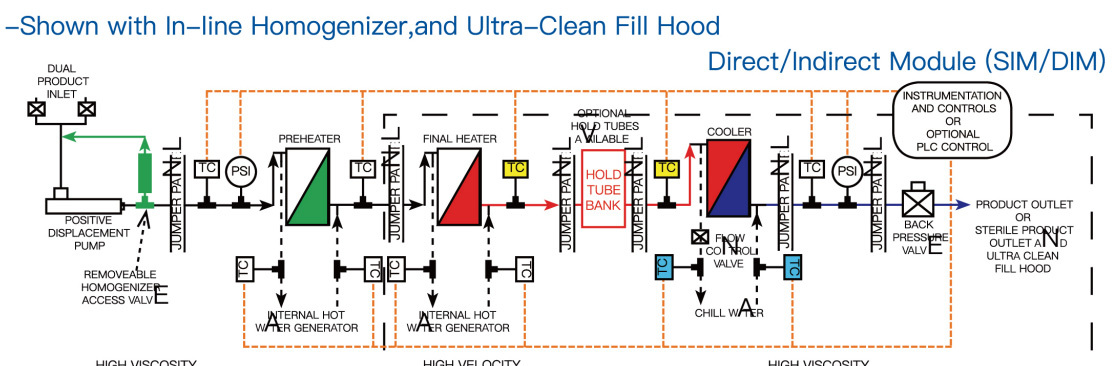

The SIM and DIM include a variable speed product pump and a digital pump speed display, allowing for seamless integration with any MicroThermics primary processing system and inline homogenizer. They also feature automatic temperature control and complete data acquisition capabilities.

Laboratory

Ultra-high Temperature/High Temperature

Short Time, Aseptic Sterilization

Equipment and Services

Simple! Economical! Process Accurate!

Example Products• Milk and Flavored Milk • Soy milk and nutritional supplements • Ice cream mixes and yogurt • Cheese sauces and puddings • Enteral nutrition • Fruit concentrates • Electrolyte beverages, juices • Tea, coffee • Soups, etc.! |

Process• Ultra-high temperature processing • Aseptic processing (low acid) • Extended shelf life (ESL) • Dry ingredient pre-wetting (DIPW) • Continuous cooking • And more! |

Process Time and Temperature• Duration (depending on flow rate) 3.6.9.15.@1L/min. -Other feasible times • Preheat Temperature: 140°-250°F(60°-121°C) • Final Heating Temperature: 220°-305°F(104°-152℃) 170°-305°F(76°-152°C)w/water heat* |

Features• Sanitary design • Product pressure transducer • Product and tool thermocouples • Hot water heated preheater • Steam injection final heater • Indirect water heated final heater * • Central jumper panel with 3 internal holding tubes • Vacuum cooler with integral vacuum pump • Indirect product cooler • Back pressure valve • Stainless steel lab bench enclosure (with casters) • *Water indirect heating on “W” models |

Dimensions• Bench height: 38 inches (0.96 meters) • Depth: 32 inches (0.8 meters) • Length: 40 inches (1.02 meters) • Instrument height: 70 inches (1.5 meters) |

Utilities• Power: 10 and 30 (specify voltage) • Steam: 80 PSI high-pressure clean dry steam • Municipal water: 2 GPM, 30 PSI • Chilled water: Minimum 5 Lpm, 30 PSI • Drain: For municipal water discharge • Compressed air: 16-20 PS, clean, dry air |

Direct UHT Processing

- Steam injection UHT processing

- 2 heaters

Indirect UHT or HTST Processing

- UHT or HTST processing

- 2 heaters

FAQ

What are the regular maintenance tasks for a website?

What are the differences between UI and UX in website design?

What types of website hosting services are there?

What is the function of website traffic statistics tools?

How to choose the right website building technology for yourself?

How to start building your own website?

ONLINE INQUIRY

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

Previous Page