DETAILED

Inconel 625 (UNS N06625)

Nickel-chromium-molybdenum alloy, the addition of niobium elements, together with molybdenum to make the alloy basically hard, thus showing high strength properties without heat treatment strengthening.

Category:

Nickel-based Alloy

Keyword:

Foreign trade

DYNAMIC DAYLIGHT

Tel:

PRODUCT DETAILS

Summary

Nickel-chromium-molybdenum alloy, the addition of niobium elements, together with molybdenum to make the alloy basically hard, thus showing high strength properties without heat treatment strengthening. The alloy is resistant to various harsh corrosion environments, especially pitting and crevice corrosion. It is used in chemical, aviation and Marine engineering, pollution control equipment, and nuclear reactors.

Metallographic structure

Inconel 625 is a solid solution type matrix reinforced face-centered cubic lattice structure alloy.

|

Chemical Composition (Weight Percentage) |

Element Composition (%) |

|

Nickel (Ni) |

58.0 minimum |

|

Chromium (Cr) |

20.0 - 23.0 |

|

Iron (Fe) |

≤5.0 |

|

Molybdenum (Mo) |

8.0 - 10.0 |

|

Niobium (Nb)+Tantalum(Ta) |

3.15 - 4.15 |

|

Titanium (Ti) |

≤0.4 |

|

Aluminum (Al) |

≤0.4 |

|

Manganese (Mn) |

≤0.5 |

|

Silicon (Si) |

≤0.5 |

|

Carbon (C) |

≤0.1 |

|

Sulfur (S) |

≤0.015 |

|

Phosphorus(P) |

≤0.015 |

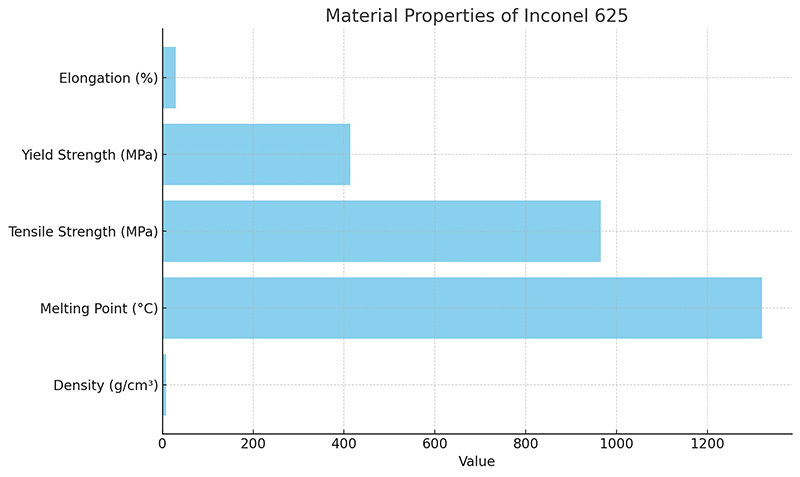

Material Properties

• Excellent resistance to corrosion from a wide range of oxidizing and reducing environments;

• Superior resistance to pitting and crevice corrosion, and no stress corrosion cracking due to nitrides;

• Excellent resistance to corrosion by inorganic acids such as nitric acid, phosphoric acid, sulfuric acid, hydrochloric acid, and mixed acids of sulfuric acid and hydrochloric acid, etc.; it can also show good corrosion resistance at a temperature of 40°C in various concentrations of hydrochloric acid solutions;

• Good workability and weldability, with no post-welding crack sensitivity;

• Certification for the manufacture of pressure vessels with wall temperatures ranging from -196°C to 450°C;

• Certified by the American Society of Corrosion Engineers (NACE) standards (MR-01-75) to meet the highest standard grade VII for use in acid gas environments.

Property Value

Density (g/cm³) 8.44

Melting Point (°C) 1290 - 1350

Tensile Strength (MPa) 827 - 1103

Yield Strength (MPa) ≥414

Elongation (%) ≥30

Corrosion resistance

625 alloy exhibits excellent corrosion resistance in many media. It has outstanding resistance to pitting, crevice corrosion, intergranular corrosion, and corrosion in chloride media. It has good resistance to inorganic acids such as nitric acid, sulfuric acid, phosphoric acid, and hydrochloric acid, and also has corrosion resistance in oxidizing and reducing environments against alkali and organic acids. It has resistance to chloride ion-induced stress corrosion cracking. It shows almost no corrosion in seawater and industrial gas environments and has high corrosion resistance to seawater and salt solutions at high temperatures. It has no sensitivity during welding. It has resistance to carburization and oxidation in static or cyclic environments and is resistant to chlorine-containing gas corrosion.

Apply

The softened and annealed carbon alloy 625 is widely used in the chemical process industry, and its good corrosion resistance and high strength enable it to be used as a thin structural component. 625 alloy can be used in contact with seawater and subjected to high mechanical stress. Typical application areas:

1. Parts of organic chemical processes containing chlorides, especially where acid chloride catalysts are used;

2. Digesters and bleaching tanks for the manufacture of paper paddles and the paper industry;

3. Absorption tower, reheater, flue gas inlet baffle, fan (wet), agitator, baffle and flue in flue gas desulfurization system;

4. For the manufacture of equipment and components for use in acidic gas environments;

5. Acetic acid and acetic anhydride reaction generator;

6. Sulfuric acid condenser.

7. Ideal for chemical processing, marine, aerospace, and nuclear applications.

FAQ

What are the regular maintenance tasks for a website?

What are the differences between UI and UX in website design?

What types of website hosting services are there?

What is the function of website traffic statistics tools?

How to choose the right website building technology for yourself?

How to start building your own website?

ONLINE INQUIRY

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

Previous Page

Next Page