DETAILED

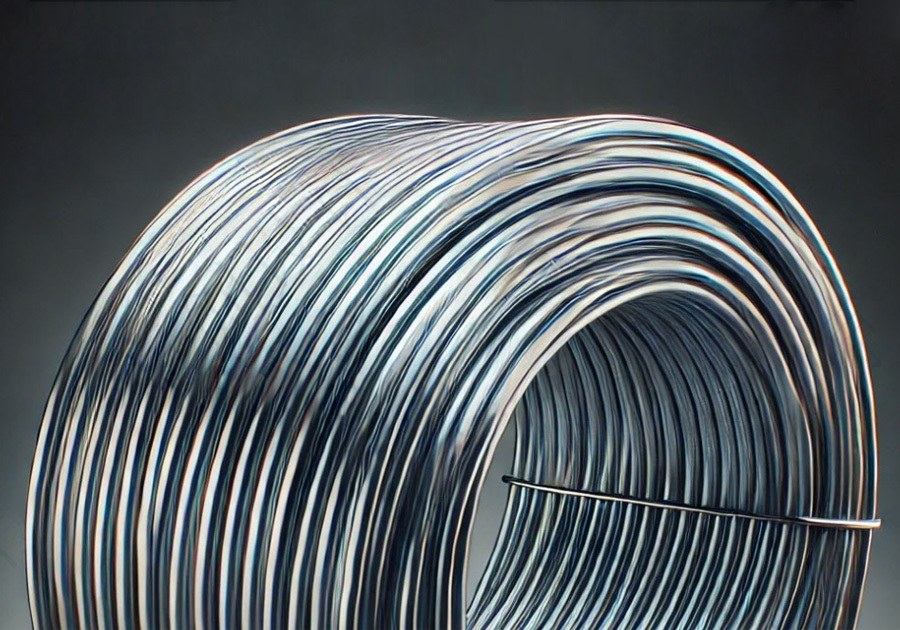

Inconel 718 (UNS N07718)

Precipitation-hardened nickelo alloys also contain a certain amount of iron, niobium and molybdenum, accompanied by small amounts of aluminum and titanium.

Category:

Nickel-based Alloy

Keyword:

Foreign trade

DYNAMIC DAYLIGHT

Tel:

PRODUCT DETAILS

Summary

Precipitation-hardened nickelo alloys also contain a certain amount of iron, niobium and molybdenum, accompanied by small amounts of aluminum and titanium. The alloy has both corrosion resistance and high strength, and has outstanding weldability and resistance to post-welding breakage. It has excellent creep fracture strength at 700℃. Used in gas turbines, rocket engines, spacecraft, nuclear reactors, pumps, molds.

Metallographic structure

Inconel 718 is an age hardened austenitic structure whose strength is largely determined by the precipitation of gamma phase (NI,AI) during heat treatment.

|

Chemical Composition (Weight Percentage) |

Element Composition (%) |

|

Nickel (Ni) |

50.0 - 55.0 |

|

Chromium (Cr) |

17.0 - 21.0 |

|

Iron (Fe) |

Balance |

|

Molybdenum (Mo) |

2.8 - 3.3 |

|

Niobium (Nb)+Tantalum(Ta) |

4.75 - 5.5 |

|

Titanium (Ti) |

0.65 - 1.15 |

|

Aluminum (Al) |

0.2 - 0.8 |

|

Manganese (Mn) |

≤0.35 |

|

Silicon (Si) |

≤0.35 |

|

Carbon (C) |

≤0.08 |

|

Sulfur (S) |

≤0.015 |

|

Copper (Cu) |

≤0.3 |

|

Phosphorus(P) |

≤0.015 |

|

Cobalt(Co) |

≤1.0 |

|

Boron(B) |

≤0.006 |

Peculiarity

• In the annealed state, has good manufacturability;

• Good tensile strength, fatigue strength, creep strength and fracture strength;

• High temperature strength at up to 700°C

• High oxidation resistance at up to 1000°C;

• Excellent mechanical properties at low temperatures;

• Good arc welding performance, no post-welding cracking sensitivity.

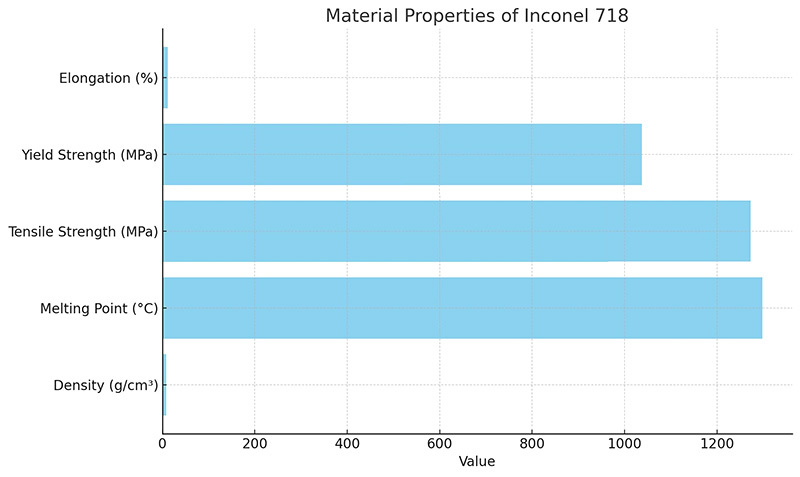

Property Value

Density (g/cm³) 8.19

Melting Point (°C) 1260 - 1336

Tensile Strength (MPa) ≥1275

Yield Strength (MPa) ≥1034

Elongation (%) ≥12

Reduction (%) ≥15

Hardness (HB) ≤(331)

Corrosion Resistance

Inconel 718 has excellent corrosion resistance to a wide range of media. Like other nickel-chromium alloys, this corrosion resistance is due to its chemical composition. Nickel has corrosion resistance to many inorganic and organic acids (in addition to strong oxidation), a mixture of acidic and alkaline acids. Nickel is also useful in its resistance to chloride ion stress corrosion cracking. Chromium has the ability to resist the corrosion of oxidizing media and sulfur compounds. Molybdenum, as we all know, plays a pitting resistance role in many media.

Apply Inconel

Inconel 718 is used in many fields due to its high temperature strength at 700°C and excellent corrosion resistance and workability. Originally used in jet engines as a turbine disc material, its creep and stress fracture resistance is now its most important application. Due to the alloy's properties, ease of processing and cost effectiveness, it has gained wide acceptance and is used today in a wide range of applications, from rotating and static components under high pressure in gas turbines and rocket engines to high-strength bolts, springs and fasteners, parts in nuclear reactors and space vehicles, and molds for extrusion and shearing. Another more important recent application is pump shafts and other offshore high pressure wellheads and downhole components and Marine engineering. Especially for drilling equipment in acidic (including hydrogen sulfide, carbon dioxide and hydrogen chloride) oil and gas Wells,and used in aerospace (jet engines, gas turbines), power plants, and chemical industries.

FAQ

What are the regular maintenance tasks for a website?

What are the differences between UI and UX in website design?

What types of website hosting services are there?

What is the function of website traffic statistics tools?

How to choose the right website building technology for yourself?

How to start building your own website?

ONLINE INQUIRY

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

Previous Page

Next Page