DETAILED

Inconel 825 (UNS N08825)

Nickel-iron-chromium alloy, with addition of molybdenum and copper, has both oxidation resistance and reducing acid properties, resistance to stress corrosion cracking and local corrosion, such as pitting and crevice corrosion.

Category:

Nickel-based Alloy

Keyword:

Foreign trade

DYNAMIC DAYLIGHT

Tel:

PRODUCT DETAILS

Summary

Nickel-iron-chromium alloy, with addition of molybdenum and copper, has both oxidation resistance and reducing acid properties, resistance to stress corrosion cracking and local corrosion, such as pitting and crevice corrosion. The alloy is particularly resistant to sulfuric acid and phosphoric acid. Used in chemical industry, pollution control equipment, oil and gas well pipeline system, nuclear fuel reprocessing, pickling equipment.

Metallographic structure

Incoloy 825 has a stable face-centered cubic lattice structure.

Here’s a detailed table summarizing the chemical composition of Inconel 825:

|

Chemical Composition (Weight Percentage) |

Element Composition (%) |

|

Nickel (Ni) |

38.0 - 46.0 |

|

Chromium (Cr) |

19.5 - 23.5 |

|

Iron (Fe) |

≤22.0 |

|

Molybdenum (Mo) |

2.5 - 3.5 |

|

Copper (Cu) |

1.5 - 3.0 |

|

Titanium (Ti) |

0.6-1.2 |

|

Manganese (Mn) |

≤1.0 |

|

Silicon (Si) |

≤0.5 |

|

Carbon (C) |

≤0.05 |

|

Sulfur (S) |

≤0.03 |

|

Aluminum (Al) |

≤0.2 |

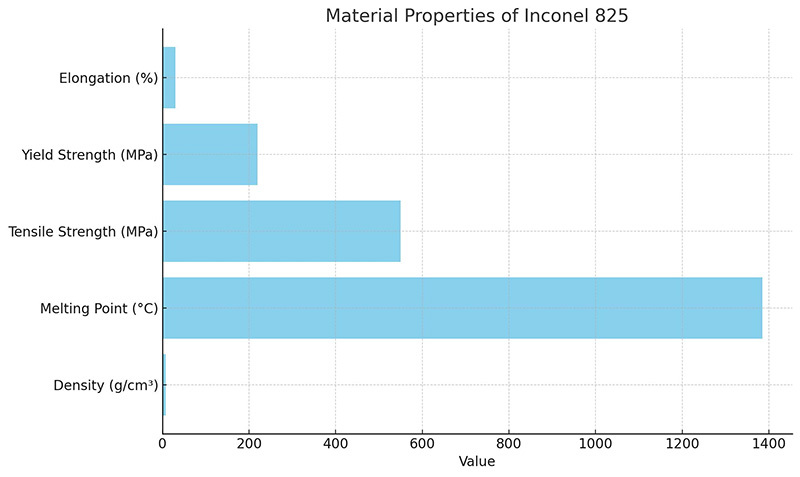

Material Properties

• Good resistance to stress corrosion cracking;

• Good resistance to spot corrosion and crevice corrosion;

• Good antioxidant and non-oxidative thermal acidity;

• Good mechanical properties at room temperature and high temperatures up to 550℃;

• Certified to manufacture pressure vessels with temperatures up to 450 ° C;

• Moderate Strength: Offers good mechanical properties while being highly ductile.

Corrosion resistance

Alloy 825 is a general purpose engineering alloy that is resistant to acid and alkali corrosion in both oxidizing and reducing environments. The high nickel composition makes the alloy have effective resistance to stress corrosion cracking. It has good corrosion resistance in a variety of media, such as sulfuric, phosphoric, nitric and organic acids, and bases such as sodium hydroxide, potassium chloride and acid chloride solutions. The higher overall performance of 825 alloy is shown in the nuclear combustion dissolver with a variety of corrosive media, such as sulfuric acid, nitric acid and sodium hydroxide are all processed in the same unit.

Apply Inconel

Incoloy 825 alloy is widely used in various industrial fields where the service temperature does not exceed 550°C.

Typical applications include:

1. Heating tubes, containers, baskets, and chains used in sulfuric acid pickling plants;

2. Sea water cooling heat exchangers, marine product piping systems, pipes and fittings for acid gas environments;

3. Heat exchangers, evaporators, washing, and dipping tubes for phosphate production;

4. Air-cooled heat exchangers for oil refining;

5. Flame-resistant alloys for high-pressure oxygen applications.

6. Commonly used in chemical processing, pollution control, oil and gas pipelines, and marine environments.

FAQ

What are the regular maintenance tasks for a website?

What are the differences between UI and UX in website design?

What types of website hosting services are there?

What is the function of website traffic statistics tools?

How to choose the right website building technology for yourself?

How to start building your own website?

ONLINE INQUIRY

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

Previous Page