DETAILED

BANTAM-SERIES

The MicroThermics® R&D system matches production thermal processes, allowing your product to go from lab to production in one step.

Category:

MicroThermics UHT/HTST

Keyword:

Foreign trade

DYNAMIC DAYLIGHT

Tel:

PRODUCT DETAILS

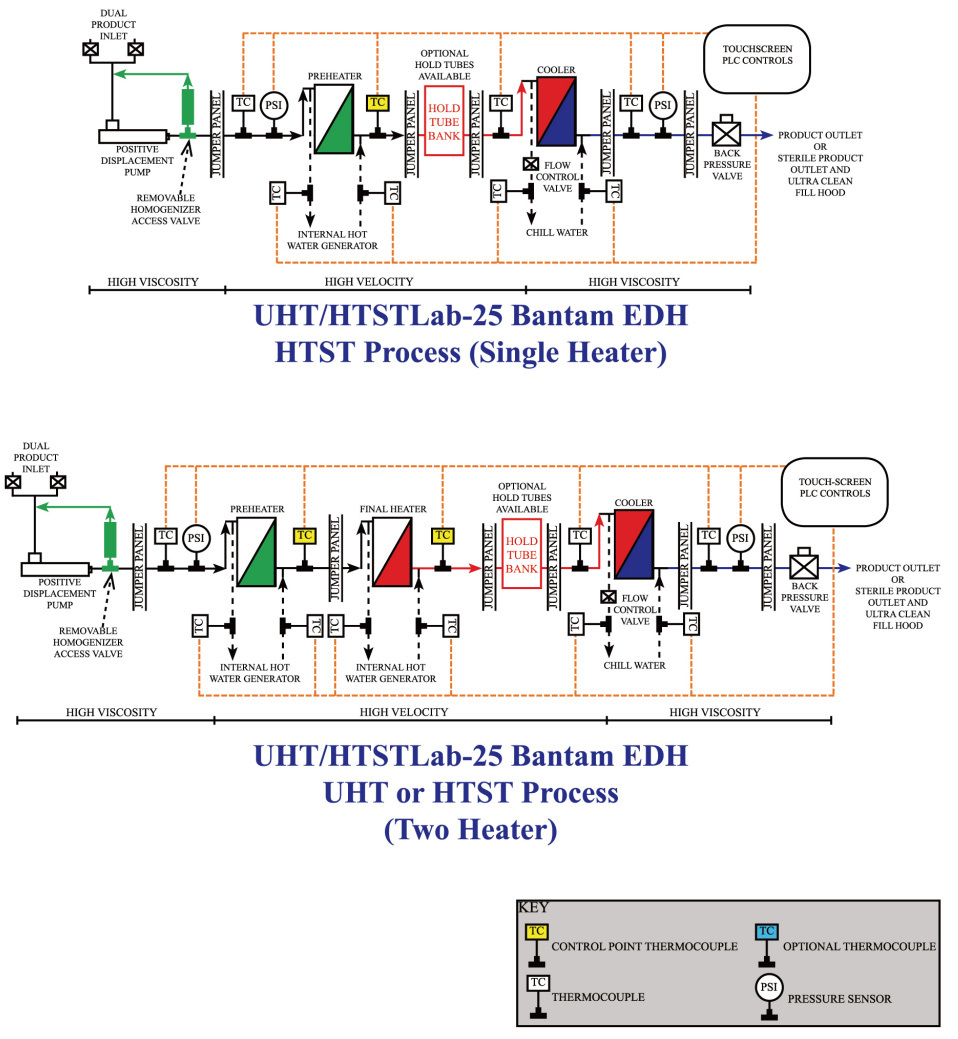

MicroThermics ® The R&D system matches production thermal processes, allowing your product to move seamlessly from the lab to production. Our systems make your research more cost-effective than any other method by rapidly producing accurate product iterations and significantly shortening your time to market. The Bantam series are low-flow, electrically heated, UHT/HTST (Ultra-High Temperature and High-Temperature Short-Time) processors. They are exceptionally attractive to R&D personnel who wish to create small batches of products. From juices and milk, to yogurt. In addition to HTST and UHT processing, they can perform hot fill and other continuous cooking processes. The system is simple to operate, extremely flexible, and has a wide range of upgrade paths to support your R&D as it scales. By precisely simulating the entire production process, we eliminate a major cause of wasted time and money: failed factory trials.

In short, investing in a MicroThermics® R&D system saves valuable time and money.

Flow Rate: 0.3 to 2.5 liters/minute

Process Range

| Model | Pre-heater | Time Available Final Heater | Viscosity Range | Time (seconds)* |

| HST-E1S | to 250'F(121°C) | None | Low to Medium | 12, 18, & 30 |

| UHT/HTST-EDH | to 250°F(121°C) | 170°-305°F(76°-152°C) | Low to Medium | 12, 18, & 30 |

*Custom

Processes batches as small as 1 liter |

Product-Model |

||

| UHT Processing: -Sterilization -Extended Shelf Life (ESL) Ultra-pasteurization HTST Pasteurization Continuous Cooking |

Hot Fill Hot Fill & Hold and more |

Milk and Flavored Milk Nutritional Supplements Enteral Nutrition Juices, Teas, and Coffees Fruit Purees |

Sauce Concentrates Applesauce, Yogurt and more! |

Features and Options

Features (Partial List) |

Optional (Partial List) |

| PLC Control and Data Acquisition Sanitary Design Simple Operation Dual Product Inlet Stepless Variable Speed Product Pump -Adjustable Flow Rate and Holding Time Three Holding Tube Product Cooler Back Pressure Valve Jump Panel Lab Benchtop Cabinet with Sink |

Additional Holding Tubes and Coolers Additional Temperature/Pressure Sensors Spare Heat Exchanger (e.g., Plate Type) Automatic Filling Control CE Marking, NRTL Certified Sterile Filling Hood/Sterile Product Outlet Enhanced PLC Control/Data Logging Inline Homogenizer Product Pump Run Dry Protection Steam Injection Processing Module Steam Generator, Chiller Spare Parts and Tool Kits, and more! |

Infrastructure Requirements

EquipmentCity Water Cooling Water Electrical: 30, 220, 440, 380 Volts Electrical: 10, 110/220 Volts |

DimensionsBenchtop Height: 38" (0.97 m) Benchtop Depth: 32" (0.85 m) Overall Length: 40.5" (1.02 m) Overall Height: 68" (1.74 m) |

Overall Process Flow Diagram (Electrically Heated Water - Hot Water Indirectly Heats Product)

FAQ

What are the regular maintenance tasks for a website?

What are the differences between UI and UX in website design?

What types of website hosting services are there?

What is the function of website traffic statistics tools?

How to choose the right website building technology for yourself?

How to start building your own website?

ONLINE INQUIRY

We will contact you within one working day. Please pay attention to your email.

RELATED PRODUCTS

Previous Page

Next Page